| Company Contact |

|---|

| Name: | Mr. Anil Amolik [Owner/Entrepreneur] |

|---|

| E-mail: | Send Message |

|---|

| Homepage: | |

|---|

| Instant Messaging: |  amolikmachines@gmail.com |

|---|

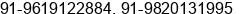

| Mobile Number: |  |

|---|

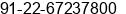

| Phone Number: |  |

|---|

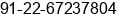

| Fax Number: |  |

|---|

| Address: | 50, Bindal Industrial Estate, Lathia Rubber Lane, Saki Naka, Andheri (E

Mumbai 400 072, Maharashtra

India |

|---|

| Average User Review | There is no review for this company - Write a review |

|---|

| Registration Date: | May. 24, 2023 |

|---|

| Last Updated: | Jan. 31, 2010 |

|---|

| Business Nature: | Manufacturing of Industrial Supplies category

|

|---|

|

| Want to contact this company?

Your inquiry will be recorded in "Member Trade Mail".

|

Put on Company Partner

|

| Recommend to your friends |

|

| Company Brief |

|---|

Amolik Precision Machines is promoted by the technocrats and they are in the machine-tool building since 1982.The Following machines are made by them.

Ball Headers,

Ball Flashers,

H & T Furnaces,

Ball Grinders,

Ball Lapping Machines,

for the manufacture of Precision Miniature Steel Balls.

Blade Grinding Machines,

Gaging & Sorting Machines.

Other machines made are :

Twin-Head Boring machines ( to simultaneously bore the TWO ENDS of Connecting Rods maintaining the Center Distance within close tolerances) , Double Disc Grinders, ( Both Vertical & Horizontal) , Flat Lapping M/ cs , Multi-spindle Milling machines, Surface Grinder ( SPM) , Conveyor Unit, etc.

|

|

| Major Products / Services |

|---|

Seller:

- Roll Forming Machine

ROLL FORMING MACHINES

Roll Forming is a continuous metal forming process which bends or “forms” sheets, strips or coiled stock into predesigned shapes or profiles by passing the metal between successive pairs of rolls that increasingly (gradually) shape it till the desired cross section is achieved, thereby adding strength and rigidity to light weight metals. Except for a slight thinning of the metal at the bend radius, the metal thickness does not get altered.

Almost any material that can be formed to the desired radius at room temperature can be roll-formed. The more ductile the material, the better it will form. This process can handle ferrous, non-ferrous, hot rolled, cold rolled, polished, plated or pre-painted materials as well.

Metals as thin as 0.127 mm and as thick as 19 mm can be roll formed depending on the machinery.

Normally cross sectional tolerances from +/ - 0.25 mm to +/ - 0.78 mm can be achieved but if better tolerances are required, a material that is amenable to such tolerance should be chosen.

- Double Disc Grinding Machine

PRINCIPLE OF OPERATION

Double Disc Grinders have been developed to Grind, two parallel flat surface, with the help of two grinding wheel faces, opposed to each other. The workpiece is advanced between the wheels, by various methods, either free floating or clamped, depending on the shapes, sizes, quantities as well as stock removals required.

- Flat Lapping Machine

Amolik Precision Machines Flat Lapping Machines are precision engineered to lap or polish all types of hard materials to a flatness of 0.3 microns (1 lightband) or better and surface roughness better than 0.4 Rz.

PRINCIPLE OF OPERATION :

An accurately conditioned lapping plate rotates in the horizontal plane, on which conditioning rings, also rotating freely in the direction of the lapping plate, carry the work pieces, with the surface to be lapped, in contact with the lapping plate. Suitably mixed lapping compound is fed onto the lapping plate which laps/ polishes the surface to be lapped and the flatness of the lapping plate is transferred to the workpiece.

- Gauging & Sorting Machine

Gaging & Sorting of Mass Produced Components

Automatic Operation

Portable

Rapid Changeover

100% Quality Control

Maintenance Free

Highly Economical

- Special Purpose Machines

We are the Manufacturer of Special Purpose Machines Such as Wire Formere, Doctors Blade Grinder & etc

|

|

- I am familiar with this company and want to review it.

|

Go to Member Menu

Go to Member Menu